The

casting of coins during the

Spring-autumn and Warring States |

The earliest coin moulds which have been found, are

spade- and knife coin moulds from the Spring-Autumn and Warring States period.

The earliest coin moulds were carved in clay, stone or bronze. The inscriptions were in intaglio and they were

used for the actual casting. The clay moulds could be used only one time, the

stone- and bronze moulds could be used several times. Since the clay moulds were destroyed after the casting,

this has been a slow an expensive way of producing coins. Soft stone types were used

for stone moulds since hard stone would crack, because of the high shift in

temperatures during the casting. The type of mould shown below, had to be

destroyed after the casting, in order to release the coins. Stone moulds were not

destroyed, and had a shape, which allowed the mould to be opened and

used again. The early carved bronze moulds could be used for the actual casting

and were not mother moulds. The ant nose money of the Chu state

is an example of direct casting in carved bronze moulds (A Xing p. 67). I

have not been able to find an explanation to why direct casting in bronze

moulds were only used in this period and not later on. If Bronze could be used for direct casting,

one should think it would have been preferred to clay and stone, since it was

more durable. My own guess is, that there must have been problems releasing the

coins after casting. The ant nose money are very simple and crude coins with

inscriptions in intaglio, maybe it was possible to cast this shape in bronze

moulds, but not the more sophisticated designs with rims, holes and inscriptions in

relief.

Later moulds from this period were usually made

from clay. The mould used for the actual casting was called a child mould

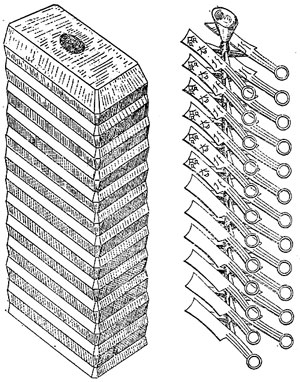

(fig. 2). The

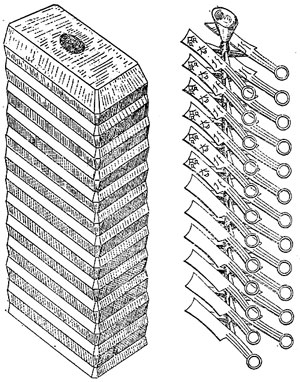

child mould was made with a so-called mother mould (fig. 1). The mother moulds

could be made of clay, stone or bronze.

The clay child molds had tenons, that fit into the opposite part of the mould,

to keep the two parts aligned. This kind of moulds had half the

impression on each side, but some types of coins were cast in moulds where only

the obverse was impressed. In that case, the reverse side of the mould was a completely flat

polished stone or brick. All the round coins shown on the Warring

States page are cast with this method.

The child moulds were piled and covered with a clay sheath to keep the

assembly together. The moulds of the Han were baked before casting, and moulds were

likely also baked in earlier times, since the clay would probably crack during

the casting, if they were only sun-dried.

Fig. 1. Mother

mould

Fig. 2. A pile of child moulds Fig. 3. The cast knife

coins before

they were broken apart.

Illustrations from Tang, Wenguang: Wo Guo Gudai Jizhong Huobi de Zhuzao Jishu.

Zhong Yuan Wenwu, 1983 nr. 2, p. 75, 76.